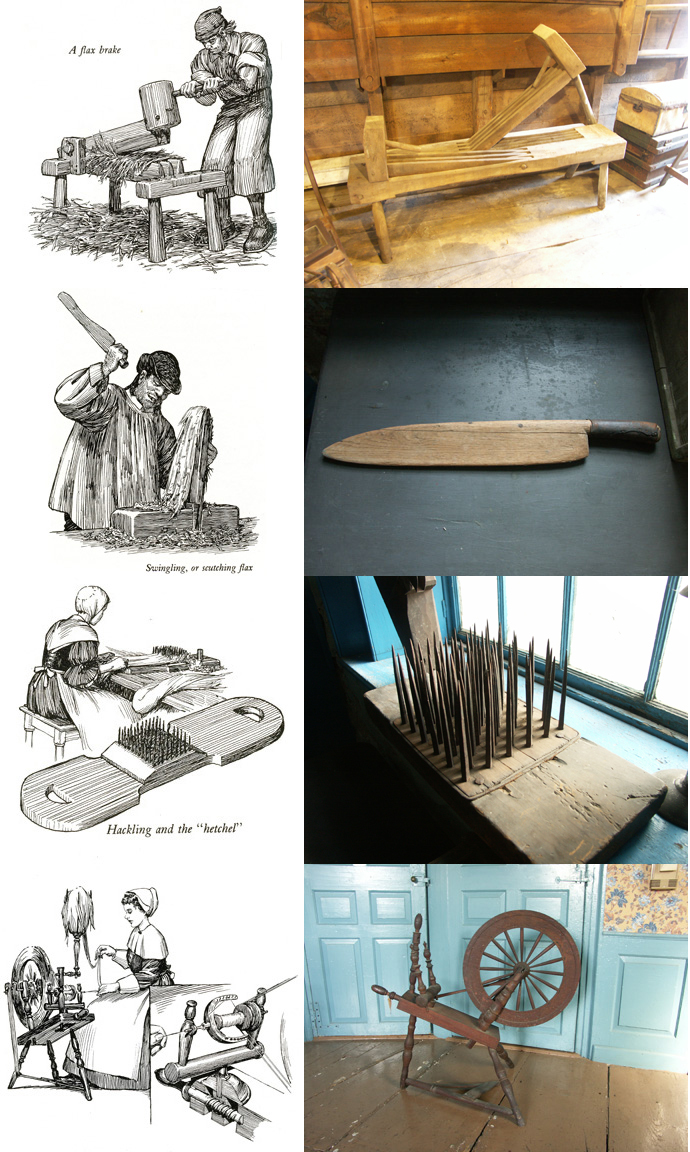

Dorchester Illustration no. 2449 Flax Processing Tools

In this period of social distancing, the Dorchester Historical Society is closed to visitors. Therefore it seems a good idea to try to share some of the items in the Society’s collections in this space from time to time.

Processing flax.

The Clapp Family Farm, now owned by the Dorchester Historical Society, has among the Clapp family’s artifacts many of the pieces involved in linen-processing.

After harvesting, flax stems were dried. Then the seed heads were removed from the stalks. Some of the seed was saved for next year’s planting, and the remainder was pressed for linseed oil. After the oil was extracted, the remains of the flax heads were fed to cattle.

Retting, or moistening, of the stalks helped to separate the fiber. In the space of a few days to a week, micro-organisms help to break down the plant structure. The stalks were then dried.

A flax break or brake has wooden blades in an arm that fit inside blades in the base. The weight of the arm of the flax break is used to smash and break the woody portion of the flax stalk into pieces, leaving the fibrous strands intact. The strands are located between the outside of the stalk and the inner core. Most brakes were designed for one person—the two-person brake at the Clapp Family Farm is quite unusual.

After breaking, a scutching knife was used to separate the broken inner and outer pieces of the stalks from the fibers. The flax is hung over an upright board, and the knife is used to gently scrape away the unwanted parts of the stalks.

The strands were then drawn through hackles or a flax comb to straighten the fibers spinning. A flax comb or hatchel or hetchel or hackle or hechel looks like a bed of nails. The flax fibers are drawn through the nails to produce spinnable fiber.

Spinning was done on a flax wheel that was a smaller version of the wool-spinning wheels often seen in historic houses.

For other resources sharing Dorchester history, see www.dorchesteratheneum.org and www.dorchesteratheneum2.org